Best practices -- Roller table

Manufacturing industry

Roller table reduces injury risk

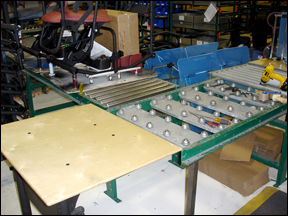

A manufacturer of stand-assist devices provided the roller tables for employees to reduce the physical requirements during assembly, disassembly and inspection of product.

Prior to the use of the roller tables, employees were required to rotate and maneuver large parts on a flat work surface during product assembly/disassembly and inspection tasks. This was a strenuous task for employees.

With the roller tables, the physical requirements for maneuvering parts have been greatly reduced. Employees can easily position parts, as needed, while performing the necessary work tasks. The tables are also height-adjustable to allow better vertical positioning of the work.

The roller tables have minimized the physical stress and related injuries associated with the back, shoulders, arms and hands/wrists.

|

Adjustable roller tables greatly reduce employee physical requirements for assembly/disassembly and inspection tasks at a manufacturer of stand-assist devices. |

|

Disclaimer: Photographs of commercially available products posted on this site are for reference purposes only and do not imply any endorsement by the Minnesota Department of Labor and Industry. The best-practices ideas have been reviewed and posted solely at the discretion of the department and should only be considered as possible examples for reducing risk factors, based on existing ergonomics guidelines. Employers and employees need to work together to identify and control ergonomics risk factors within the workplace to better ensure changes made to a work process will be effective in reducing risk factors and maintaining work efficiency.